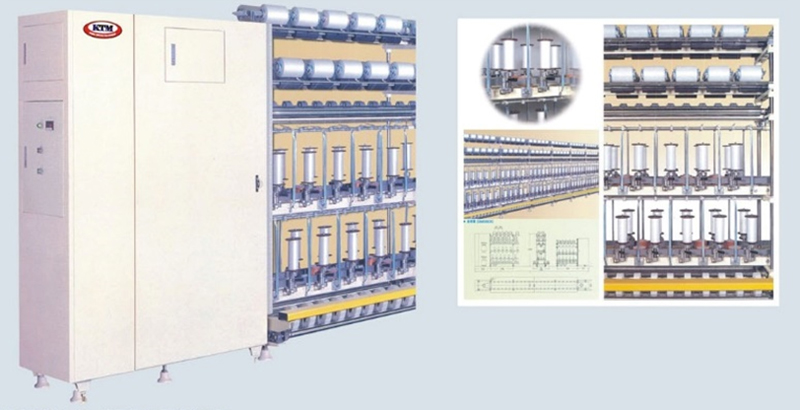

KTM608 SERIES

| KTM socks knitting machine is single cylinder machine for production a wide assortments of high quality socks. |

|---|

GUIDE FOR FUNCTIONS

| KTM socks machine KTM608 series adopt single cylinder for producing high quality socks in various pattern and styles with fully electronic system. Controller makes socks manufacture easy in various pattern and all function are controlled perfectly by electronic valve, stepping motor and servo motor. It maximized the efficiency on heel and toe knitting with two down picker. Beside the sensor for user convenience will help you to solve error and problem of the machine. |

|

TECHNOLOGY FEATURES

| ▷ 16 step lift-up type actuator (Stable needle selecting during knitting) ▷ Adopt USB drive (can be use flash memory) ▷ Automatic lubrication using microcomputer which controlled oiler ▷ Possibility to control the scales of socks with feeding elastic yarn by stepping motor ▷ LCD allowed the operator to easily keep track of knitting conditions including error message, stop signal, production quality and speed ▷ Included English, Chinese and Korean. ▷ Adopt UPS system – the pattern can be saved after accidentally power off or other problem and the last work procedure can be automatically continued after restarting ▷ Pattern designing system is brief and easy to operate. It can be run on common computer with windows 98/2000/XP/vista and Windows 7 ▷ 1 main feeder (8 yarn finger) +5 color feeders(3 yarn fingers each feeder) ▷ Two down picker system (Can be increase production quality to reduce rotation of needle cylinder and knit semi 3D socks) ▷ Socks ejection sensor (optional) ▷ Double elastic device for two kind of color (optional) |

| SPECIFICATION | KT608 | KT608S | KT608TM | KT608TMS | KT608T | KT608TS | KT608TL | KT608BS | KT608EX | |

|---|---|---|---|---|---|---|---|---|---|---|

| CYLINDER DIAMETR | 3,5” | 3.5” | 3.75” | 3.75” | 4” | 4” | 4” | 5.25” | 3,75”/4” | |

| NEEDLE COUNT | 72N~240N | 72N~168N | 72N~168N | 170N”~200N” | 72N~168N | 170N~200N | 48N~72N | 200N~280N | 72N~156N | |

| ACTUATOR | 16 STEP | 16 STEP | 16STEP | 16STEP | 16STEP | 16STEP | 16STEP | 16step | 16step +6step | |

| USE FOR | PLAIN SOCKS | O | O | O | O | X | O | O | O | O |

| TERRY SOCKS | X | O | O | O | O | O | X | O | O | |

| POLA SOCKS | X | X | X | X | X | X | X | X | O | |

| SPEED(RPM) | PLAIN SOCKS | 350 | 320 | 320 | 320 | X | 320 | 350 | 250 | 320 |

| TERRY SOCKS | X | 280 | 280 | 280 | 320 | 280 | 200 | 280 | ||

| DRIVE MOTOR | 0.85 | |||||||||

| FAN MOTOR | 1.1 | |||||||||

| CONTROLLER | 0.8 | |||||||||

| STANDARD ELECTRIC SUPPLY | 220V/380V/440V/ 3 PHASE 50/60HZ | |||||||||

| FLOOR SPACE (W*L*H, cm) | 1500X1200X2400 | |||||||||

| PACKING DIMENTION | 1500X1050X1730 (H) | |||||||||

| NET/GROSS WEIGHT | 330Kg / 400Kg | |||||||||

KG-305 / FULLY COMPUTERISED GLOVE KNITTING MACHINE

|

SPECIFICATION

| Model Name | HS-305 |

|---|---|

| Knitting Size | 5G 7G 8G 10G |

| Knitting Speed (RPM) | Finger:180 / Body:200 |

| Control Panel | Electronic Control Panel One Touch Operation |

| Electrical Power | 220V, 250W, 50-60HZ |

| Machine Dimension | L1230*W650*H1750 |

| Weight | 250kg |

KOTM-24P Electronic Socks Setting Machine.

|

Features:

| 1. The machine requires electricity, water and compressed air, there is absolutely no requirement of oil, gas or any boilers. 2. The machine is highly economical, very easy in operation, very user friendly, requires very less man-power as compared to rotary steam setting machine. 3. One can easily regulate the revolution speed and the setting time of the machine with a slight adjustment of the touch screen type controller. 4. The machine has a unique feature that the iron press-setting of each socks, is given twice in only one cycle of operation. Working cycle Boarding – Steaming chamber be electricity small boiler – Pressing(ironing) chamber by hot electric aluminum board(the presser is ironing twice in each socks) – Drying chamber by infrared heater-cooling by spray. |

SPECIFICATION

| Boarding Forms | 24pcs |

|---|---|

| Production(8hr) | 200 to 250 Dozen |

| Power | 3P, 50/60hz, 220/380v |

| Power requirement | 12kw |

| Power consumption | 7.3kw/hr |

| Air Requirement | 4kg/cm2 |

| Water consumption | 10L/hour |

| Controller | Touch screen, inverter control |

| Driving Type | Circular type, adjustable speed |

| Temperature adjustable | Up to 250°C |

| Man power Requirement | Two person |

| Weight(kg) | 1,000 |

| Floor Space(mm) | W1000*L3200*H1800 |

| Packing Dimension | W1150*L3460*H2150 |

KD-01/ HIGH PERFORMANCE AUTOMATIC LINKING

| High Productivity Designed double head and gives you high quality and high productivity. Less Noise Realised noiseless based on our technology No point mark Designed no point mark employing chain type Clean working environment Realised clean working environment employing vacuum cleaner, after being linked, scraps are absorbed completely by the ring blower, and it can realized clean environment. |

|

| Needle | 90#(4117) 100#(4118) |

|---|---|

| Capacity/8Hours | 300Dozens per 8Hours |

| Usable Yarn Count | Nylon 30D/2 20/2 |

| Motor | 0,2Kw 60Hz/50Hz |

| Net Weight | 140kg |

| Gross Weight | 200kg |

| Packing Dimension | 900mm*600mm*1700mm |

| Measurement | 0,918CBM |

KS-6F SERIES / Single Cylinder Drumless Socks Knitting Machine

| HS Series is fully computerized single cylinder socks knitting machine. Allow for more color combination, more patterns, more sock designs, and higher productivity. Application for men’s, women’s, kids socks, long socks, pant socks, terry sport socks and etc. |

|---|

| 1. One main feeder plus five pattern feeders for possibility of 15 colors. 2. Automatic Stitch quality control by stepping motors. 3. All working condition appeared graphic LCD display. 4. Servo motor adopted for high knitting speed. 5. Internal UPS function can keep knitting data when power off. 6. USB system adopted for easier data reading and storage. 7. Minimized and easy operation system adopted. 8. High speed, high production capacity, around 30 dozens for ankle socks in 24hrs; 9. Error self-check and machine stops automatically, error information showing on LCD 10. Automatic lubrication device using microcomputer controller oiler. 11. Possibility to modify the density, speed, cycles for each step. 12. Modification of needle number and gauge can do on keyboard after changing cylinder. |

|

SPECIFICATION

| DIVISION | MODEL | KS-606M | KS-606P | KS-606PS |

|---|---|---|---|---|

| DIA OF CYLINDER | 3 1/2” | 3 3/4” | 3 3/4” | |

| NUMBER OF NEEDLES | 40-220N | 72-200N | 40-108N | |

| SOCKS TYPE | PLAIN | TERRY | PLAIN/TERRY | |

| KNITTING SPEED | 350RPM | 280RPM | 300RPM | |

| POWER REQUIRED | A,C SERVO DRIVE | 1.0 KW | ||

| BLOWER | 0.75 KW | 0.95 KW | 0.95KW | |

| CONTROL BOX | 0.7 KW | |||

| FLOOR SPACE | 120X140 CM | |||

DH-SD-240 TYPE / COVERING MACHINE (SINGLE&DOUBLE)

|

|

Model DH-SD is newly developed “Combination Machine” of single and double covering, which can be used for multipurpose High Speed Revolution: By the adoption of precise spindles, fine bearings and minute vibration absorbing rubber, it has been made possible to obtain the high speed revolution. Save Electric Consumptions: Loss of energy and noise can be reduced by the adoption of special curved arrangement of spindles. Single & Double: The change of covering from single to double can be easily obtained by moving the spindle angle line,(At double not necessary the additional spindle’s) Production Development: By the increase of spindle’s. The mass production is very efficient. |